Our Product Range

Magnetic particle inspection

Magnetic Particle Inspection (MPI) is a non destructive testing (NDT) method used to find surface and shallow subsurface flaws like cracks and inclusions in ferromagnetic materials (such as iron and steel). It works by inducing a magnetic field in the part and applying fine magnetic particles; these particles accumulate at areas where the magnetic field "leaks" from a discontinuity, making the defect visible to an inspector. MPI is a widely used, fast, and relatively easy-to-apply technique favoured by industries like aerospace, automotive, and petrochemicals

Liquid Penetrant test

liquid penetrant testing (LPT), also known as dye penetrant inspection, is a non-destructive testing method that uses capillary action to reveal surface-breaking defects in non-porous materials. The process involves applying a liquid penetrant to a clean surface, which is drawn into fine cracks and pores. After a set dwell time, excess penetrant is removed, and a developer is applied to draw the trapped penetrant back to the surface, creating visible indications of any flaws. This technique is widely used for inspecting metals, ceramics, and plastics in industries like aerospace and manufacturing because it is sensitive, cost-effective, and works on complex shapes. However, it only detects surface-level defects, requires thorough pre-cleaning, and cannot be used on porous materials.

Ultrasonic testing

Ultrasonic testing (UT) is a family of non-destructive testing (NDT) techniques that use high-frequency sound waves to detect internal flaws or measure a material's properties without damaging it. The technology is similar to medical ultrasound, but for industrial use.

Metallurgical testing

Metallurgical testing is the comprehensive process of evaluating the chemical, physical, and mechanical properties of metals and alloys to ensure they meet the quality, safety, and performance standards required for their intended use. It involves a variety of destructive and non-destructive techniques, such as tensile and hardness tests to measure strength and durability, chemical analysis to confirm elemental composition, and microscopic examination (metallography) to assess internal structure and identify flaws. By providing crucial insights into a material's integrity, metallurgical testing is an essential tool for quality control, failure analysis, material selection, and process optimization across a wide range of industries, including aerospace, construction, and manufacturing

Hardness testing

Hardness testing measures a material's resistance to permanent surface deformation, like indentation or scratching. It involves pressing a harder, known object (an indenter) into the material's surface with a calibrated force and then measuring the depth of penetration or size of the resulting impression. Common methods include Brinell, Rockwell, and Vickers tests, each using different indenters, loads, and measurement techniques to determine a specific hardness value for the material.

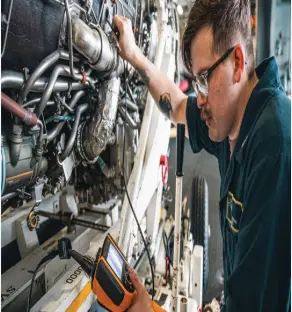

Boroscope testing

Borescope testing, also known as remote visual inspection (RVI), is a non-destructive testing (NDT) method that uses a borescope to examine the interiors of hard-to-reach cavities. A borescope is an optical instrument with a camera and light on a rigid or flexible probe that sends images to a display, allowing for internal inspection without dismantling the equipment

Bolt induction heating service

A bolt induction heating service uses electromagnetic fields to rapidly and precisely heat bolts, expanding them for easier removal or tightening. This method is a fast, labour-saving, and precise alternative to flame heating, widely used in industries like turbines for safe and efficient maintenance of large equipment. Service providers offer expertise, tailored solutions, and efficient, cost-effective processes to minimize collateral damage and preserve component integrity